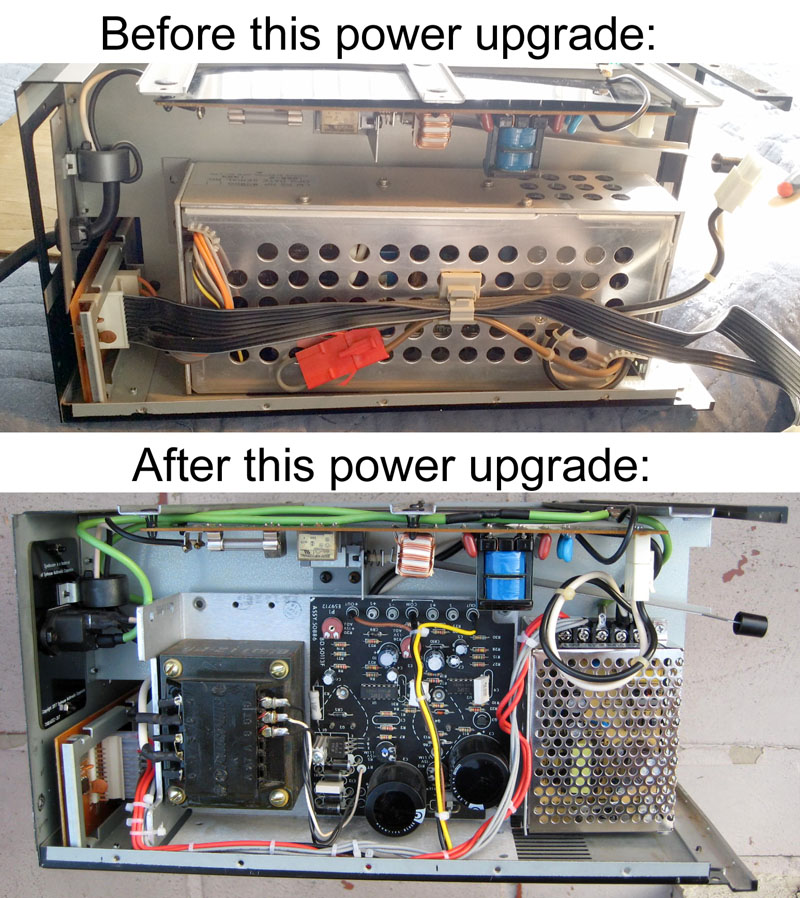

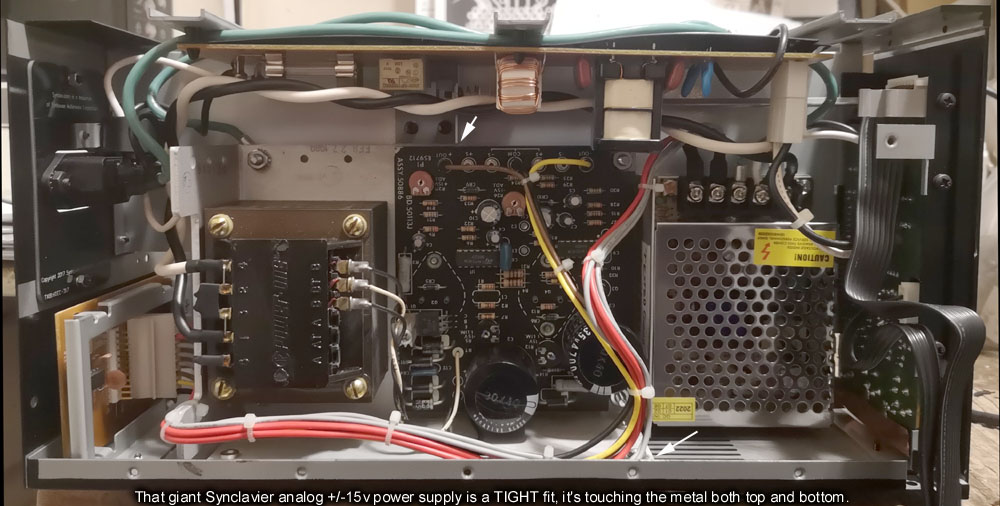

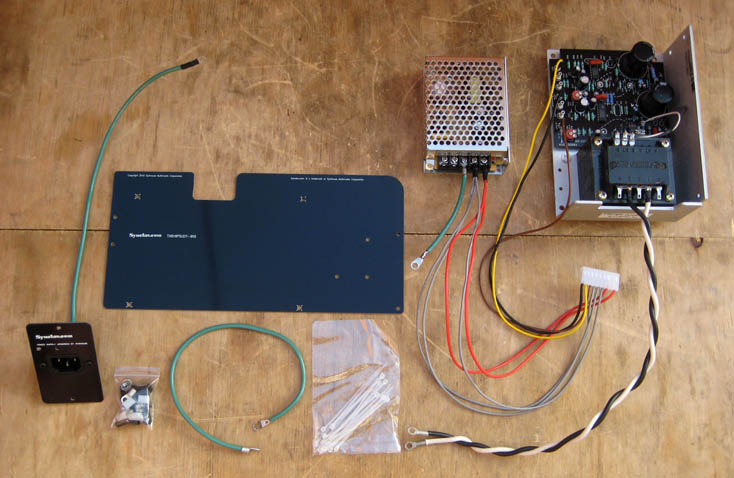

Notes on product appearance and photos shown: Most items shown in the photos on this product page are versions that existed from 6/2019 through 2021. By 7/2025 every single piece of the upgrade, aside from the central Synclavier analog power supply itself---which is the whole point of this design versus the trash anyone else is trying to do---had been changed and improved to proper factory made items and better materials to replace the prototype/hand made of surplus parts items supplied the first few years when it had been anticipated that very, very few of these kits would be sold, and possibly only few could even be made. The installation method remains the same for now, just follow the installation photos. The earlier photos that still remain on this page, the installation page, and in other places showing this Synhouse product may show earlier versions of the parts. For example, the stiff gasoline-proof green AWG 10 triple ground wires w/unplated copper strands (now factory made in very flexible green AWG 10 triple ground wires w/tin plated copper strands for improved solderability, featuring the tin plated copper fully flat star washer/ring terminals for stacking to the star grounding point, made to the latest revision which is perfect), the black/white AWG 14 AC twist wires from 2006 studio surplus (now factory made w/new machine twisted AWG 14 wiring), main 9-way 5-color half factory/half handmade wiring harness (went to fully factory made once the exact lengths were determined, then to fully factory made in the better, preferred factory that makes those TX816 and some Synclavier and SP1200 wiring harnesses for Synhouse), main digital PSU (preferred factory unreachable for two years, out of business by 2022, replaced by various other suppliers those 3 years that were difficult to certify, replaced by preferred factory better than the first one doing a first production then a massive second production once Synhouse factory work was fully resumed), single use black FR4 drilling template (made in 15 different versions, most hand modified, but at least four factory versions existed [3/2017, 9/2019, 1/2021, and 4/2023], now a single use white paper drilling template which delayed a 2nd price increase and 3rd shipping price increase since the shipping box no longer had to be a foot long), black IEC AC inlet and FR4 IEC panel (went from whatever factory/surplus IEC sockets were in stock at Synhouse over the years to a new IEC socket from the preferred factory, and to a black steel IEC panel more similar to the old Yamaha panel that gets removed/discarded, plus it is M3 metric tapped like the old one from Yamaha to remove another two items from the hardware packet, this was great expense and difficulty enabled only by five years of the surprising success of this kit and the use of that same IEC socket/panel in another Synhouse product), miscellaneous mismatched black/red/green (No choice b/c muh "supply chain crisis" with 115 ships lined up off the L.A. coast [when not a single ship or dock crew in the world had refused to work even once] had Synhouse buying very approximately sized heat shrink tubing of miscellaneous colors at Harbor Freight tools while All Electronics was closed for lockdown. Fun fact: Not one person working at or shopping at that store died of the world's most deadliest pandemic knowst to man.) heat shrink tubing installed by Synhouse and supplied in hardware packet (went to matching heat shrink tubing from preferred factory), cable ties from 1999 Synhouse stock (went to new stock cable ties from better factory), hardware packet (had many parts replaced with better, more exact parts, initially changing 2/each steel nuts and spring washers to 2/each single Keps nuts for ease and efficiency, then replaced entirely with the tapped black steel IEC inlet panel requiring no nuts on the back at all, though the very, very limited production of this upgrade doesn't allow the usual Synhouse designed and manufactured hardware/fasteners to be produced, it must be off the shelf from somewhere), and, most importantly, it can be seen that the fully soldered ring terminals which had been whatever was in stock at Synhouse for decades (mostly odd factory closeout lots from the wonderful, wonderful All Electronics in the city with no skies Van Nuys, permanently out of business in 2023, fellow shoppers at any time might include many L.A. electronic music techs, and two ex-Linn Electronics, Inc. people come to mind) were changed to three very precise new parts from the preferred factory, especially the tin plated heavy cast pure copper ring terminals in two sizes, still fully soldered, and avoided accepting ANYTHING less, and no one else has those (lame attempts at competing with this power supply upgrade don't supply but suggest using crap crimp connectors). The usual applies, as everyone else says: The company reserves the right to change the product from the appearance shown.

(VIDEO)

Need 230v Euro power? It's supplied to anyone ordering from Europe or otherwise requesting it.